Animal Sound… Talks! Real-time Sound Analysis for Health Monitoring in Livestock

Abstract

Precision livestock farming (PLF) is a livestock management technology that puts the living organism in the centre and equipment around to measure the animal’s response. Sound-based PLF techniques have significant advantages over other technologies such as cameras or accelerometers. Besides the fact that microphones are contactless and relatively cheap, there is no need for a direct line of sight, while large groups of animals can be monitored with a single sensor in a room. The objective of this paper is to present an example of a successful sound- based PLF product, in order to encourage the reader to consider performing sound-based PLF research in the future. The respiratory distress monitor, a tool that automatically monitors the respiratory health status of a group of pigs, was selected for discussion in this paper. Results of five different use cases are discussed to show the effectiveness of the respiratory distress monitor as an early warning tool for respiratory problems in a pig house. It is demonstrated that the tool works for the early detection of animal responses due to technical issues (ventilation problems) and health issues in a wide range of different conditions in commercial European pig houses.

Keywords: PLF, acoustic monitoring, respiratory distress monitor, early warning, cough

1. Introduction

In recent years, several factors have stressed traditional livestock farming. Firstly, the global meat demand has grown extremely as the world population continues to grow. Furthermore, income per capita is increasing, particularly in the upcoming industries like the BRIC-countries. This enables massive new groups of people to consume meat. Another trend specific to consumers in developed countries is the augmented concern towards ethical and environmentally friendly meat production. Additionally, there is a clear need for a reduction in the use of antibiotics in intensive livestock production (Aarestrup, 2012; Kimman et al., 2010). Finally, the global market has seen a shift towards fewer, internationally operating retailers. As the retail market uses price as a primary means of competition, livestock farmers face ever lower margins per animal, which in turn forces them to increase efficiency and exploit economies of scale. This leads to a lower number of farms with more animals per farm (Marquer et al., 2014).

To increase efficiency in livestock farming, Hanton and Leach proposed to combine the information of biological processes with principles and practices of modern engineering and technology (Hanton and Leach, 1981). In essence, livestock farming is described as a process control technology with the living organism at its centre. Berckmans expanded the idea of livestock farming as a process control technology and coined the term Precision Livestock Farming (PLF) (Berckmans, 2006). PLF is based on three guiding principles. Firstly, PLF does not aim to replace the farmer but intends to be a decision support tool. Secondly, the animal is to be considered the most crucial part in the biological production process. Lastly, three conditions are important for favourable monitoring and control: the animal variables need to be monitored continuously, the prediction (expectation) of the animal variable should be reliable with respect to environmental changes and the prediction needs to be integrated with on-line measurements into an analysing algorithm.

Different kinds of sensors are employed to facilitate PLF in a practical setup, e.g., cameras (CCTV, infra-red, 3D, thermal…), accelerometers, flow meters… A particularly interesting type of PLF techniques uses microphones to capture sound. Sound contains a lot of useful information about the animal and its environment (communication, health, welfare). Capturing sound with a microphone is contactless, does not depend on lighting conditions (these pose a real problem for many cameras in practical conditions), allows the monitoring of large groups of animals with a single sensor, is relatively cheap, does not need a direct line of sight, copes with a wide range of temperatures, can be used indoor and outdoor and has an acceptable lifetime.

Recently, a number of examples of sound-based PLF-technology have emerged in different species. Moura et al. showed how thermal (dis-) comfort can be monitored in broilers based on sound analysis (Moura et al., 2008), while Aydin et al. demonstrated the monitoring of broiler feed intake by pecking sounds (Aydin et al., 2014). Rhim et al. developed oestrus detection in sows based on vocalisations (Rhim et al., 2008); Hillman et al. used acoustic monitoring of pigs for the detection of thermal (dis-) comfort (Hillmann et al., 2004), while Manteuffel et al. developed a pig scream detection algorithm (Manteuffel and Schön, 2002).

The objective of this paper is to present an example of a successful PLF application based on sound, in order to encourage the reader to consider sound-based PLF research. The respiratory distress monitor for pigs was selected as the PLF example in this paper. The automatically generated respiratory distress index was compared to findings of the farmer, the veterinarian and a trained assessor.

2. Materials and Methods

2.1. EU-PLF setup

The data used for this paper were obtained in the EU-funded Collaborative Project EU-PLF (EU-PLF, 2012). Pig sounds were captured during 60 fattening rounds in 40 compartments divided over 10 fattening pig farms (4 compartments per farm) across Europe. The different farms had significantly different climatological conditions, housing layout, pig breeds and management styles. The farmer and local veterinarian kept track of their findings in logbooks, without access to use the respiratory distress monitor in real-time (the results were only discussed retrospectively when the fattening batches were finished). Moreover, trained animal experts performed welfare & health assessments of key indicators at discrete moments during the fattening period. The assessments were used as a reference in this paper and were the results of a 10-minute standardised manual cough count in the compartment.

2.2. The measurement system

The hardware used to capture the sounds was a SoundTalks’ SOMO+ sound recording device. The phantom-powered (i.e., DC electric power is transmitted through the microphone cables to operate the microphones that contain active electronic circuitry) microphones were connected in a balanced way. This permits the use of long microphone cables, with limited susceptibility to noise. The microphones were typically centred with respect to the position of the animals that were monitored (e.g., pig pen). The microphones were fixed at a height of 2 metres to be close enough to animals, yet not too close for the animals to reach them. Recordings were continuous (24/24, 7d/w) in files of 5 minutes duration. The recording parameters were set to 16 signed integer bit resolution, with a sampling rate of 22.05 kHz (standard WAV file format). The embedded sound card was fanless and protected from the harsh environment by a sealed enclosure. The microphone was protected from the environment by a thin and flexible cover, designed to not interfere with the sound acquisition in the frequency range of interest, i.e., from 1 kHz to 5 kHz (Ferrari et al., 2008). The equipment, much like similar PLF technologies, was subject to a range of robustness-related issues typical in the farm environment (Banhazi et al., 2014).

2.3. Pig cough monitoring

The idea to use automated cough detection in pigs as an early warning tool for respiratory problems in a pig house is not new. Van Hirtum et al. first developed algorithms to discriminate pathological from non-pathological pig coughs (Van Hirtum, 2002). A physiological model to describe the various phases of cough was later developed and Guarino et al. translated the academic results to a field test on a commercial pig fattening farm (Guarino et al., 2008). Ferrari et al. did a characterisation of pig cough sounds using time and frequency-derived parameters (Ferrari et al., 2008), while Exadaktylos et al. proposed a first real-time algorithm for cough detection in controlled conditions (Exadaktylos et al., 2008). Further details on these studies are described in the paper by Vandermeulen et al. (2013).

The link between automatically measured cough and anomalies in respiratory porcine behaviour has been validated extensively in three clinical field trials (Finger et al., 2014; Genzow et al., 2014a, 2014b). The field trials took place on a commercial pig fattening farm, during three different fattening batches. Various clinical tests such as (discrete) serum drawings were used as diagnostics. The serum drawings were tested for Swine Influenza Virus (SIV), Mycoplasma Hyopneumoniae (M. Hyo) and Porcine reproductive and respiratory syndrome virus (PRRSV). The work showed that the automated cough measurement was an objective and unbiased indicator of porcine respiratory health for all three trials.

2.4. Respiratory distress monitor

In 2011, the scientific results of pig cough detection algorithms, as described above, were

translated into a commercial product (the respiratory distress monitor). A number of challenges inherent to the process of commercialising scientific research have been faced. The objective of producing the commercial tool was not to count all individual pig coughs accurately in an automated way, but to have a robust tool that gives an early and reliable warning of respiratory problems in a commercial pig house. As pig cough sounds differ between seasons, between race of pigs, between types and stages of diseases (co-infections) and conditions (acoustical, climatological, management etc.), the algorithms that were developed in laboratory conditions must be modified to build a robust tool that works in real practice. All case studies in section 3 are described in terms of a respiratory distress index (RD-index). The RD-index is a measure for respiratory distress, relative to the number of animals present in the compartment. RD-values below 10 usually indicate moments with low respiratory distress, while higher RD-values indicate respiratory problems. In all the graphs, a single value of the RD-index is shown per day. It is shown in section 3 that an early warning based on the RD-index was often several days faster than the observation by the farmer / veterinarian, who sometimes even did not detect the respiratory problem.

3. Results and Discussion

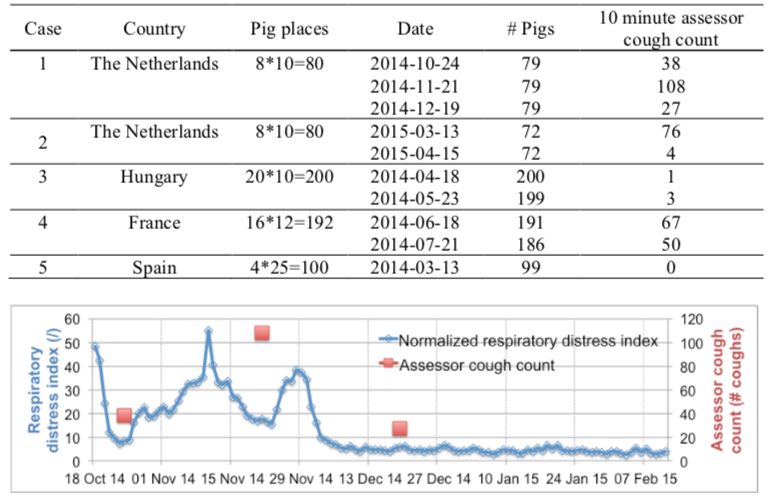

Table 1 summarises the country, the total number of pig places and the assessment data of the different case studies. The total number of pig places in the compartment is given in the format a*b=c, with ‘a’ the number of pens, ‘b’ the number of animals per pen and ‘c’ the total capacity of animals in the compartment. The last three columns describe the assessment data, i.e., the date of the assessment, the actual number of pigs in the compartment during the assessment and the number of coughs counted in 10 minutes by the assessor.

3.1. Case 1: Co-infection PRRSV, SIV and M. Hyo

Figure 1 shows the evolution of the respiratory distress as a function of time, measured on a farm in the Netherlands. On October 18th 2014, 79 piglets of 10 weeks old entered the compartment. Necropsy (PCR-analysis of lung section) was performed on two piglets that had died before reaching the age of 10 weeks. Both piglets were positive for Mycoplasma Hyopneumoniae (M. Hyo) and negative for Influenza-A virus (SIV), PRRSV NA and PRRSV NA-HP. One piglet was further positive for PRRSV EU and weakly positive for PCV-2, while the other piglet was negative for both. All animals received vaccination against PCV-2, but not against PRRSV, M. Hyo and Influenza.

Table 1: Overview of the country, total number of pig places and assessment data per case.

Figure 1: Case 1, the Netherlands, co-infection PRRSV, SIV and M. Hyo.

The veterinarian of the farm decided that treatment with doxycycline and sodium salicylate was necessary when the piglets entered the compartment on October 18th. This treatment was stopped after 4 days. It is clear that the respiratory distress index in this period is in good correlation with the observation of the veterinarian. The index starts at a high level (48), before the effect of the treatment becomes clear and the index drops to values below 10 after 5 days.

From October 23rd onwards, the respiratory distress was rising to reach a peak level of 55 on November 10th. The farmer and veterinarian, who could not consult the graph of respiratory distress in this two-direction blind test, were unaware of further respiratory problems in this period and no treatment was given to the animals. A routine diagnostic test (oral fluid multiplex PCR test) on November 12th revealed that the animals were positive for Mycoplasma Hyorhinis, weakly positive for Mycoplasma Hyopneumoniae and negative for PRCV, PRRSV, SIV, PCMV and PCV-2. In neighbouring compartments, positive cases of SIV were found. Because high coughing levels were noticed, an 8-day treatment with doxycycline and sodium salicylate was restarted on November 13th. This type of treatment usually does not last longer than 5 days on this farm, but the severity of the respiratory problem forced a longer treatment period. The effect of the treatment is clearly visible, as the respiratory index drops in this period. The added value of the respiratory distress monitor is clear in this case as the rise of distress could have been noticed more than 2 weeks earlier. Faster treatment of the animals would have resulted in less economic loss (higher average daily gain, lower feed conversion ratio, etc.).

A third increase in respiratory distress was visible around November 29th. Based on oral fluid samples from neighbouring compartments, the veterinarian believes that this increase was most probably caused by a combination of diseases, i.e., PRRSV, SIV and M. Hyo. After November 29th, the respiratory distress index returned to normal values, i.e., below 10.

The automatically generated respiratory distress index is in good correlation with the findings of the human assessor, as a high number of coughs were counted on 3 occasions. It is clear that the continuous automated measurement of respiratory distress gives a much clearer picture of the complex respiratory situation on the farm. In combination with diagnostics and the knowledge from farmer and veterinarian, the respiratory distress monitor proves to be a tool with added value and economic impact.

3.2. Case 2: SIV

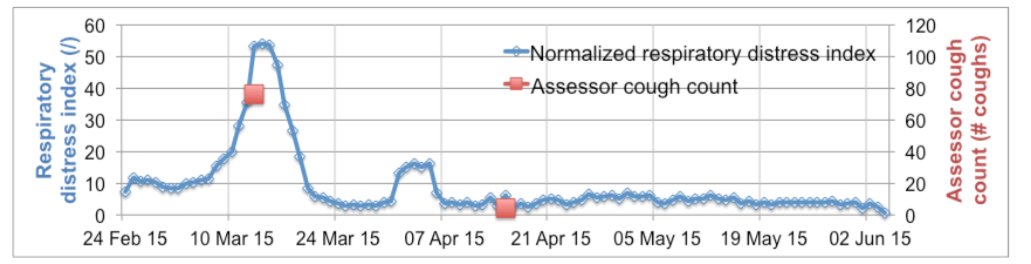

Figure 2 shows the evolution of the respiratory distress in function of time, measured on a farm in the Netherlands. On February 24th 2015, 72 piglets of 10 weeks old were placed in the compartment.

Figure 2: Case 2, the Netherlands, SIV.

The clear increase in the respiratory distress index from March 8th–14th corresponds very well with the high number of coughs (76) counted by the assessor on March 13th. Only on March 12th, i.e., about 4 days after the increase in the automatically generated respiratory distress index, the farmer noticed an increased level of coughs during his routine check. A 3-day group treatment with doxycycline and sodium salicylate was immediately started and from March 15th onwards, the respiratory index continued to drop. A level below 10 was reached again on March19th. Based on oral fluid samples (from this compartment and other compartments in the farm), the veterinarian concludes that SIV is the probable cause of the respiratory distress.

A second, smaller peak in the respiratory distress index is visible between April 1st–7th. The farmer noticed an increase in coughing in a few animals on April 2nd, i.e., again one day later than the sudden increase in the respiratory distress index. A few animals were treated with doxycycline and sodium salicylate for 3 days. The respiratory distress graph correlates well with the observation of the farmer. The lower respiratory distress values in the second peak can be explained by a lower number of animals that were affected by the disease in this period. The hypothesis of the veterinarian is that the majority of the animals were already infected with SIV during the first peak, while the remaining animals (a smaller group) were only affected a few weeks later. Further diagnostics information to support this hypothesis was not available here.

The low value of the assessor cough count on April 15th (4) is in excellent correlation with the respiratory distress index, which had already dropped below 10 on April 6th.

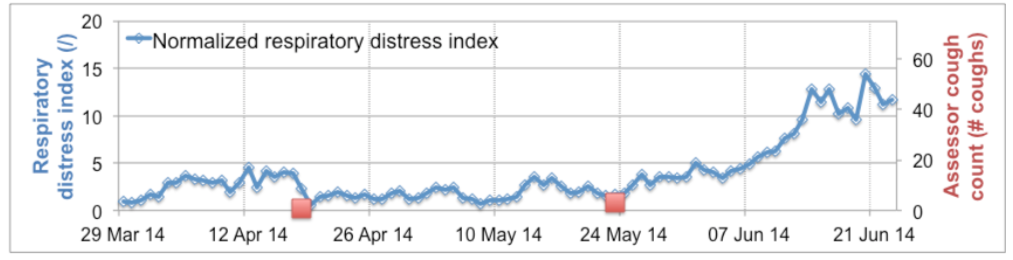

3.3. Case 3: pleuritis / pneumonia

Figure 3 shows the evolution of the respiratory distress index for a batch of fattening pigs on a Hungarian farm. The farmer did not notice any respiratory problems during the round and no medical treatment was given to the animals. The findings of the assessor (1, resp. 3 coughs) support the idea that there were few respiratory problems on April 18th and May 23rd. Near the end of the batch though, the respiratory distress index starts to increase to reach a maximal value of 14 just before the end of the fattening round. Slaughterhouse data of 25 selected pigs revealed that 12/25 animals had pneumonia while 3/25 animals had pleuritis. No diagnostic data was available to retrieve the exact cause of the disease, but it is clear that there was a respiratory problem that remained unnoticed by the farmer. The hypothesis is that earlier medical intervention (triggered by the respiratory distress monitor) would have reduced the economic losses for the farmer.

Figure 3: Case 3, Hungary, pleuritis / pneumonia.

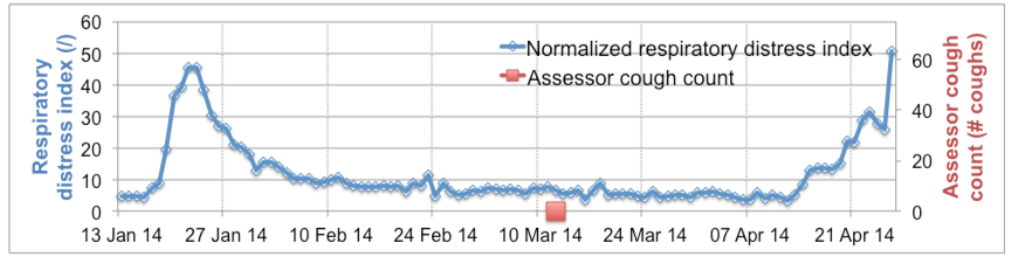

3.4. Case 4: air washer problems

Case 4 presents the data of a fattening batch between the end of April till the end of August 2014 on a farm in France. Between May 30th and June 5th, there was some missing data due to humming (undesired noise caused by the electric circuit) in the microphone. Before entering the fattening compartment, the piglets were vaccinated against M. Hyo and PRCV; no further vaccines were given after April 21st.

Figure 4: Case 4, France, problems with air washer.

On May 21st, the farmer first noticed that something was wrong on the farm. Unaware of the cause of the problem at that time, he reported that indoor temperatures were unusually high (31°C) although the ventilation was working at maximal capacity. The situation was monitored more precisely and on May 30th a blocked (by dust and bacteria) air washer was identified as the underlying cause of the problem. The farm was equipped with an air washer in order to reduce the dust and odour levels. As a first solution, 1 of the 3 layers of the air washer was removed on May 30th to increase the airflow through the pig house. The farmer reported that the pigs started to cough more in the next days and on June 3rd a 6-day treatment with aspirin and vitamin C was started. The veterinarian indicated that the pigs were suffering from pneumonia, although the exact underlying pathogens were unknown. The respiratory distress index clearly shows a good correlation with the findings of the farmer and the veterinarian in this period, with a peak up to 36 on June 7th.

Since the problems with the air washer persisted, the farmer removed the remaining 2 layers of the air washer on June 13th. Interestingly, the farmer reported that the cough levels dropped significantly after the treatment period of June 3rd–8th, but not to levels he would consider normal for his farm. The latter is reflected by the respiratory distress index, although there was a clear secondary peak around July 2nd that was not noticed by the famer (and therefore no treatment was given). Additional diagnostics and / or treatment seemed appropriate and would have resulted in less economic losses due to higher feed conversion rates and lower average daily weight gains. The manual coughs counted by the assessor (respectively 67 and 50 coughs in 10 minutes) confirmed that there were respiratory problems in this batch.

3.5. Case 5: thermal shock

Figure 5 shows the evolution of the respiratory distress index measured on a fattening farm in Spain. Except for the beginning and the end of the fattening round, the RD-index was below scale 10 indicating no significant respiratory problems. The farmer and the veterinarian did not notice any respiratory problems during this fattening batch; hence no medical treatment was given during this round. The only medical interventions were traditional vaccinations against Aujeszky on January 25th and February 16th. The assessment on March 13th (0 coughs) further supports the idea that the respiratory status of the pigs was good during the middle of the fattening round.

Figure 5: Case 5 Spain, thermal shock.

The peak in respiratory distress index in the beginning of the round is very characteristic and similar peaks were measured for other batches / compartments on this farm. The peaks were a lot higher during winter times and occurred typically within the first week after placing the animals in the compartment. As the building was very open (suited to the hot climate that occurs during most of the year) and the farmer did not pre-heat the compartment prior to the arrival of the pigs, the hypothesis was that the thermal shock between the nursery and the fattening compartment makes the pigs vulnerable to different respiratory infections. However, no further data was available to support this hypothesis, although it is well known that thermal shock can have these effects

From April 12th onwards, a clear increase in the respiratory index is visible again. The farmer did not notice any respiratory problems and no actions were taken. Based on previous examples, it was assumed that there was a respiratory problem and that the economic losses could have been reduced if the farmer would have taken appropriate measures near the beginning (pre-heating) and end of the batch (treatment).

In summary, this paper presented five different cases to analyse the reliability of the continuous, automated monitoring of respiratory distress in pigs.

4. Conclusions

This work demonstrated how the tool gives earlier warnings (up to 2 weeks earlier!) compared to a situation where the farmer and veterinarian rely on their own routine observations without the monitor. Different causes of respiratory problems ((co-) infections as well as technical problems with air washers and ventilation) have all been shown to result in an increase in automated respiratory distress measure.

Acknowledgements

The authors gratefully acknowledge the European Community for financial participation in Collaborative Project EU-PLF KBBE.2012.1.1-02-311825 under the Seventh Framework Programme. This work is further supported by funding of the IWT Baekeland (Agentschap voor Innovatie door Wetenschap en Technologie — Agency for Innovation by Science and Technology in Flanders) (No. IWT 140245).

References

Aarestrup, F. 2012. Sustainable farming: Get pigs off antibiotics. Nature 486, 465–466.

Aydin, A., Bahr, C., Viazzi, S., Exadaktylos, V., Buyse, J., and Berckmans, D. 2014. A novel method to automatically measure the feed intake of broiler chickens by sound technology. Comput. Electron. Agric. 101, 17–23.

Banhazi, T., Vranken, E., Berckmans, D., Rooijakkers, L., and Berckmans, D. 2014. Practical problems associated with large scale deployment of PLF technologies on commercial farms. In Sessions of the 65th EAAP Annual Meeting. Copenhagen, Denmark: Wageningen Academic Publishers. 105-112

Berckmans, D. 2006. Automatic on-line monitoring of animals by precision livestock farming. In Livestock Production and Society, R. Geers, and F. Madec, eds. Wageningen Academic Publishers. 51–54.

Exadaktylos, V., Silva, M., Aerts, J.M., Taylor, C.J., and Berckmans, D. 2008. Real-time recognition of sick pig cough sounds. Comput. Electron. Agric. 63, 207–214.

Ferrari, S., Silva, M., Guarino, M., and Berckmans, D. 2008. Analysis of cough sounds for diagnosis of respiratory infections in intensive pig farming. Trans. ASABE 51, 1051–1055.

Finger, G., Hemeryck, M., Gomez-Duran, O., and Genzow, M. 2014. Practical application of the Pig Cough Monitor in a German fattening pig herd with PRDC. In Proceedings of the 23rd IPVS Congress, Cancun, Mexico. 207–208.

Genzow, M., Gomez-Duran, O., Hemeryck, M., and Finger, G. 2014a. Course of cough in two batches of fattening pigs with different respiratory pathogen exposure. In Proceedings of the 23rd IPVS Congress, Cancun, Mexico. 212-213

Genzow, M., Gomez-Duran, O., Strutzberg-Minder, K., Finger, G., and Hemeryck, M. 2014b. Monitoring of a commercial fattening herd by means of the Pig Cough Monitor and oral fluid diagnostics. In Proceedings of the 23rd IPVS Congress, Cancun, Mexico. 205-206.

Guarino, M., Jans, P., Costa, A., Aerts, J.-M., and Berckmans, D. 2008. Field test of algorithm for automatic cough detection in pig houses. Comput. Electron. Agric. 62, 22–28.

Hanton, J.P., and Leach, H.A. 1981. Electronic livestock identification system. U.S. patent 4 262 632 A

Hillmann, E., Mayer, C., Schön, P.-C., Puppe, B., and Schrader, L. 2004. Vocalisation of domestic pigs (Sus scrofa domestica) as an indicator for their adaptation towards ambient temperatures. Appl. Anim. Behav. Sci. 89, 195–206.

Van Hirtum, A. 2002. The acoustics of coughing. PhD Thesis. KU Leuven. Leuven, Belgium.

Kimman, T., Smits, M., Kemp, B., Wever, P., and Verheijden, J. 2010. Banning Antibiotics, Reducing Resistance, Preventing and Fighting Infections: White Paper on Research Enabling an Antibiotic-free’ Animal Husbandry. Wageningen Academic UR.

Manteuffel, G., and Schön, P.C. 2002. Measuring pig welfare by automatic monitoring of stress calls. Agrar. Berichte 29. 110-118

Marquer, P., Rabade, T., and Forti, R. 2014. Pig farming in the European Union: considerable variations from one Member State to another. Eurostat Stat. Focus 2014. 15/2014, 1-12

Moura, D.J. de, Nääs, I. de A., Alves, E.C. de S., Carvalho, T.M.R. de, do Vale, M.M., and Lima, K.A.O. de 2008. Noise analysis to evaluate chick thermal comfort. Sci. Agric. 65, 438– 443.

Rhim, S.J., Kim, M.J., Lee, J.Y., Kim, N.R., and Kang, J.H. 2008. Characteristics of Estrus- related Vocalizations of Sows after Artificial Insemination. J. Anim. Sci. Technol. 50, 401–406.

Vandermeulen, J., Decré, W., Berckmans, D., Exadaktylos, V., Bahr, C., and Berckmans, D. 2013. The Pig Cough Monitor: from research topic to commercial product. In Proceedings of Precision Livestock Farming ‘13, Leuven, Belgium. Berckmans D., J. Vandermeulen eds. Rosseels Printing, 717–723.